Hydraulic Indexing Fixture |

| Hydraulic Indexing for HMC |

- Hydraulic and electrical connections thru the top mounted rotary coupler allow full 360° B-axis rotation.

- Clamping pressure 5000psi / actuation pressure 1800psi.

- 7 stations randomly selected with 4 M-codes, 8 M-codes for two pallet machines.

- Each station defined with shimable hard stops and are held in position with 1000ft/lb torque.

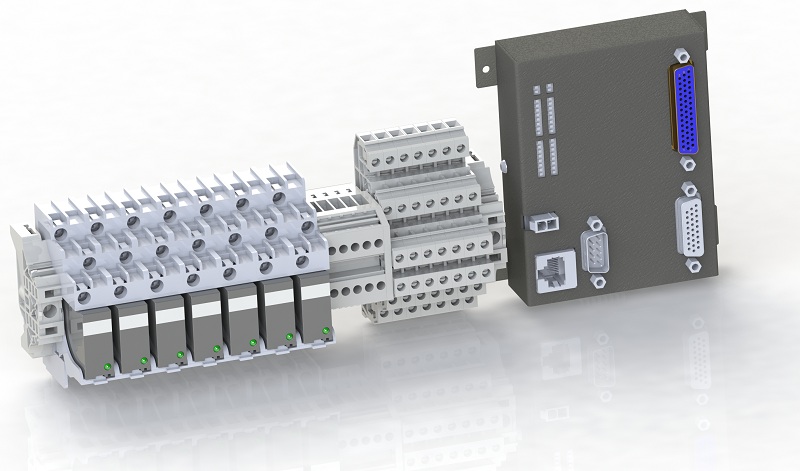

- Integrated PLC to operate rotation and stops with positive internal air pressure protect electronics.

- 1-right and 1-left workpiece - 1-operation.

- Fully hardened gears with extra surface hardness.

- Large diameter thru shaft 7 ½” with rotary seal for clamping pressure.

- Main Bearing 210mm pre-loaded cross roller

- Workpieces are held in place with pre-clamp retension

- With the 4” thick upright, the fixture sits on a 400mm pallet and fits within a 500mm swing with the workpieces in place.

- The cutout in the upper right hand area of the fixture is to allow access to the backside of the workpieces.

- Fixtures without the need for access to the backside of the part can have full 360° indexing using shortest distance

Images below: Front view with covers removed, Electronics

|

|

|

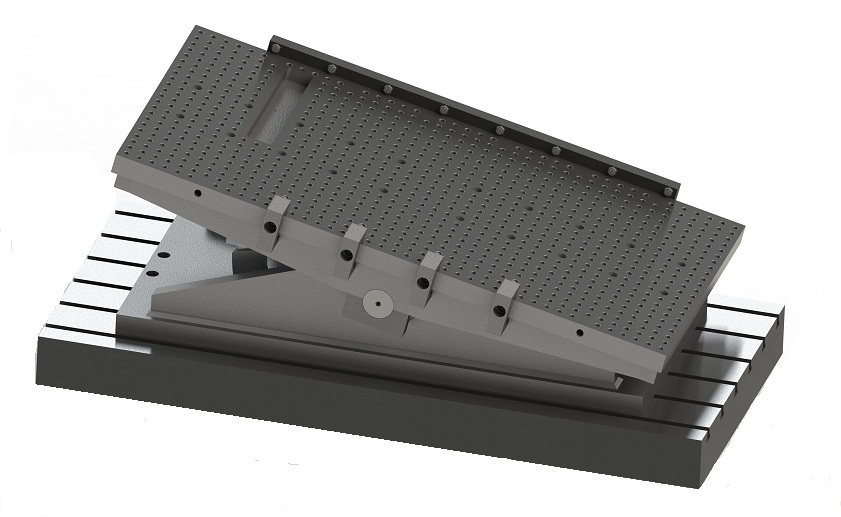

| Hydraulic Indexing for VMC |

- Two stations defined by four shimable rest pads

- Rest pads shielded by sheet metal guides and bellows (not shown)

- Operated by M-code with 'at station' feedback or palm buttons

- Full Stevens grid pattern

- Dual hydraulic cylinders with 1100psi for actuation

- Stations held in place with hydraulic pressure

- Large 3" I.D.taper roller bearings for pivot

- Optional front clamps and rear rail with carbide inserted grippers

- This fixture has a relief slot in the table to clear a feature on the workpiece

- The top surface is finish precision ground in assembly

|

|

|