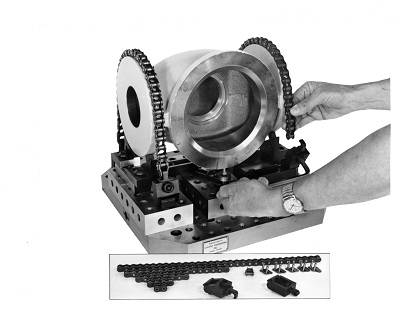

Building Modular Setups |

6 independent locating points required to fully constrain workpiece in x, y, and z. On many workpieces, it is convenient to categorize locating points into:

|

|

To eliminate indicating or probing requirements, use the built-in accuracy of the qualified surfaces and bushing locations of Stevens Setup Components. |

|

Clamps should directly oppose locators. Check for spindle tooling clearances when positioning clamps. Check for spindle tooling clearances when positioning clamps. |

|