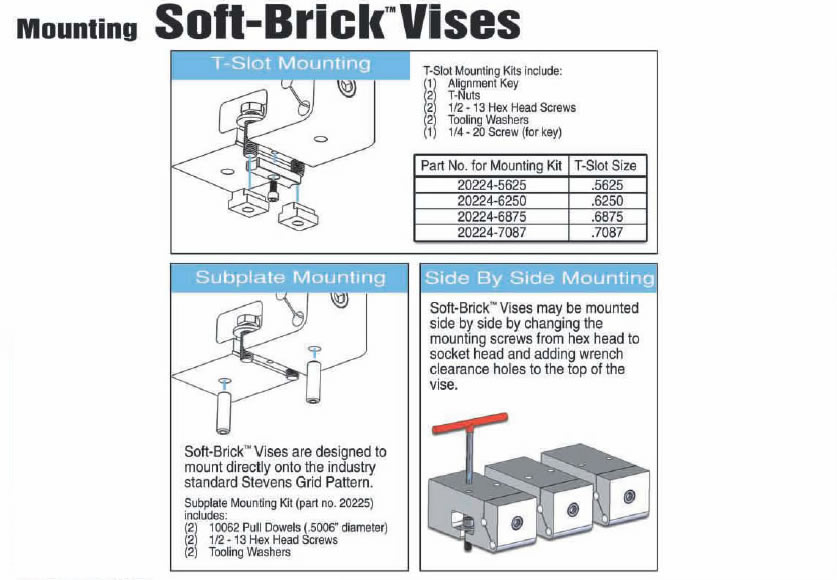

- All Soft Bricks are designed to mount to Stevens Engineering Subplates and Tombstones with Stevens 5" or 2.5" Grid Pattern. Shown below is the top view of Softbricks mounted on a Stevens subplate and represents the different Spacinges / part densities that can be achieved by each style. Instructions are provided below for machining part cavity into softbricks.

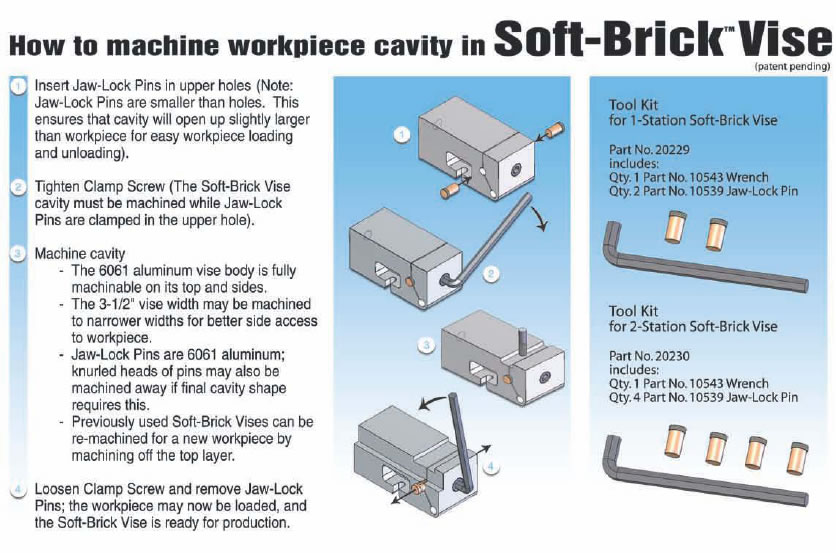

- A totally new concept in workholding, the Stevens Soft-BrickTM Vise eliminates the need for changing jaws on soft jaw vises. The vise needs no soft jaws because the vise itself is a soft jaw. Made from 6061 aluminum, the low-cost vise can be machined by users with cavities to fit specific workpieces.

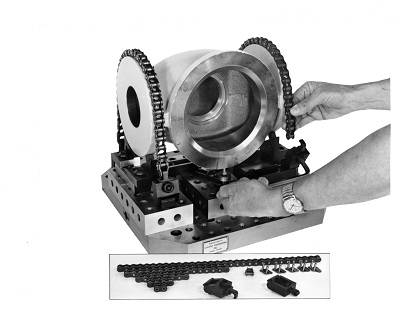

- The patented design incorporates a jaw-lock pin to clamp the empty vise while machining the cavity. Then, the jaw~lock pin is removed and the workpiece can be clamped with up to 5000 Ibs of clamping pressure. Hardened steel male and female threads and thrust bearing provide durability.

|