Stevens Subplates |

|||

|

|||

|

|||

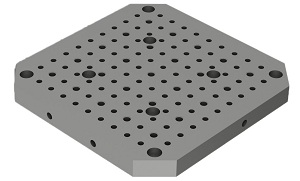

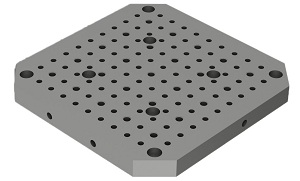

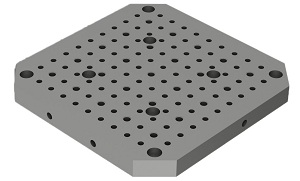

1/2-13 threads on 1.25" centers 1/2" bushings on 5" centers 1.4" subplate thickness |

3/4-10 threads on 2" centers 3/4" bushings on 8" centers 1.65" subplate thickness |

||

| See our Subplate Selection by Machine Manufacturer section for pricing information. | |||

Subplate alignment to the machine axes is generally done with an indicator in the machine spindle by refrerencing two Subplate bushings. Additional locating features for positioning Subplates are available if desired. Subplates are available in one piece up to 120" x 40". Larger areas are covered by multi-section.  |

Subplate locating features to match machine pallet locators are recommended to simplify positioning and alignment of Subplates on horizontal mills.  |

||

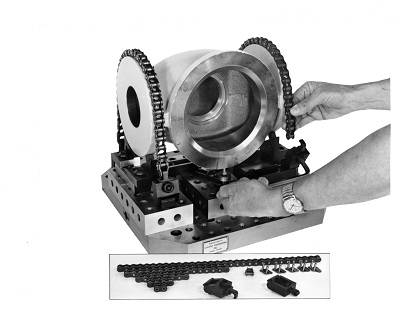

Stevens Subplates and accessories are ideal for ram-type EDM machines. Stevens Chip Plugs are recommended to keep debris aout of threaded holes and bushed holes in Subplate. |

|||

|

|||||||||||||||

is recommended on knee type mills using glood coolant. Trough allows for return of coolant to the sump. Chip filter screens are included. |

|

With a bushing on every other hole it is possible to get finer adjustments for fixture placement. Some of our accessories like the 20251 Short Softbrick Vise use the high density pattern. |

|

is a lower cost alternative to the basic pattern because of fewer threaded holes. This pattern is used for quick mounting of dedicated fixtures, project plates, and some accessories. It is not suitable for building fixtures with modular setup components |

|

are used on machines used mainly for flat, low-profile work that needs to be raised closer to the spindle nose. Riser section may be integral with Subplate or may be removable if Subplat is also to be used in its standard thickness. |

|

is available as an option onall Stevens Subplates. Deep-etched letters and numbers facilitate documenting location of locators and clamps for future duplication of setups. |

|

Multiple Subplates used on machines with pallet changers should be ordered match ground unless machine control is capable of storing pallet offsets independently. |

|

Using Big Kaiser's zero point clamping system to hold tombstones or fixture plates. For use in either horizontal or vertical applications. All plumbing is contained in channels underneath the plate for Un-clamp and if needed, the Turbo function. Quick connect fittings protrude at the edge of the plate in a place which is convenient. Manual or solinoid air valves can also be supplied. |

|