Modular Fixturing VS. Dedicated ToolingThe Pros and Cons By Robert L. Coope, President SME Technical Paper #TE93-388 |

| - INTRODUCTION The introduction of the modular fixturing concept for machine tool applications has met with varying degrees of acceptance on the part of decision makers in this country. On one hand, managers with a strong bias in favor of traditional workholding techniques are reluctant to embrace new approaches. This reluctance translates into lost opportunities for important gains in productivity. The opposite extreme is the manager who is totally enamored with the modular concept and is wrongly advised by an over-zealous salesman to dispose of all of his permanent dedicated tooling. This extreme can have unfavorable consequences of a different nature. |

| The purpose of the following is to suggest a way of analyzing the pluses and minuses of continued use of dedicated fixtures versus the all-modular approach of creating temporary holding fixtures using modular accessories. A measured case-by-case consideration of each approach and how it fits in with specific product mixes and production requirements can yield good results. |

| - SMALL-LOT PRODUCTION In discussing the relative merits of dedicated fixtures and modular fixtures, it is assumed that the reader is involved in small-lot production runs and is consequently interested in reducing 1) setup time, 2) tooling expense, and 3) tooling lead time. Whether dedicated tooling or the all-modular approach is used, a proven way to reduce machine setup time is to use an accurate grid pattern for locating fixtures, vises, and other accessories. The ability to pin fixtures and components into an accurate grid pattern eliminates the need to indicate or probe for alignment and position. |

| While an accurate grid pattern greatly reduces machine setup time, the decision must be made whether and when to go one step further in utilizing this same grid pattern to address the other factors in small-lot production: tooling expense and tooling lead time. When should a custom dedicated fixture be designed and built? When should the all-modular approach be used? |

| - CASE STUDY Exhibit 1 is an example of a permanent holding fixture specifically designed to locate and hold a particular workpiece. The fixture has been designed to dowel and screw to two Stevens Narrow Profile Angle Plates which are in turn doweled and screwed to a Stevens Subplate. This fixture plate onto which the workpiece mounts was designed and built in a few days using a stock pre-jigbored tooling plate. Setup time is minimal because components pin into the standard grid pattern. |

Exhibit 1A Exhibit 1B |

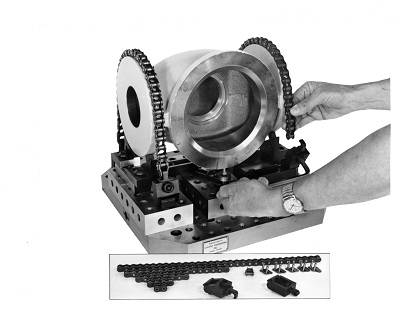

| Exhibit 2 illustrates how the same workpiece shown in exhibit 1 could be set up using all-modular setup components. This fixture was designed and built in 3-4 hours using standard off-the-shelf setup hardware. If the modular fixture is documented with photographs, sketches, or CAD drawings, it can later be rebuilt in about 15 minutes and will repeat location of the workpiece from the prior production run. |

Exhibit 2A Exhibit 2B |

| Both of these approaches offer the benefits of a standard grid pattern, but there are advantages and disadvantages when comparing the two approaches to each other. |

| - ADVANTAGES OF DEDICATED TOOLING When given a clean sheet of paper, an adequate budget, and sufficient lead time, a skilled tool designer can design a custom workholding fixture that is ideally suited to the application. Not limited to standard hardware, the designer may create custom details that offer the strength and rigidity to withstand aggressive cutting forces without sacrificing compactness or workpiece loading ease. Locators and clamps may be sized and shaped specifically for the part they are being used to hold. Tapped and bored holes may be incorporated into the fixture at any location. |

| The all-modular approach generally makes some sacrifices in terms of 1) rigidity and strength, 2) ease and speed in loading the workpiece, or 3) overall compactness of the fixture. |

| Modular accessories are designed for maximum versatility in a wide range of applications. At times, a clamp or locator made from all-modular components may consist of more than one component coupled together with some possible overall loss in rigidity versus a one-piece custom detail used in a dedicated fixture. Rigidity in an all-modular setup often comes at the expense of overall compactness. As a result, a larger working envelope may be required to accommodate a modular fixture. |

| A custom fixture can be optimized for the ergonomic convenience of the operator, making loading of the workpiece easy. Careful planning of the all-modular fixture can minimize inconveniences but not always eliminate them. |

| - ADVANTAGES OF THE ALL-MODULAR APPROACH When given a clean sheet of paper, an adequate budget, and sufficient lead time, a skilled tool designer can design a custom workholding fixture that is ideally suited to the application. Not limited to standard hardware, the designer may create custom details that offer the strength and rigidity to withstand aggressive cutting forces without sacrificing compactness or workpiece loading ease. Locators and clamps may be sized and shaped specifically for the part they are being used to hold. Tapped and bored holes may be incorporated into the fixture at any location. |

| The all-modular approach generally makes some sacrifices in terms of 1) rigidity and strength, 2) ease and speed in loading the workpiece, or 3) overall compactness of the fixture. |

| Modular accessories are designed for maximum versatility in a wide range of applications. At times, a clamp or locator made from all-modular components may consist of more than one component coupled together with some possible overall loss in rigidity versus a one-piece custom detail used in a dedicated fixture. Rigidity in an all-modular setup often comes at the expense of overall compactness. As a result, a larger working envelope may be required to accommodate a modular fixture. |

| A custom fixture can be optimized for the ergonomic convenience of the operator, making loading of the workpiece easy. Careful planning of the all-modular fixture can minimize inconveniences but not always eliminate them. |

| - ECONOMIC EVALUATION As indicated earlier, there are benefits to be gained by the use of an accurate grid pattern regardless of whether dedicated fixtures or the all-modular approach is used. There are additional and quite different benefits to be gained by the use of all-modular setup components. It is important to understand both types of cost savings in evaluating the potential for the use of modular tooling in widely differing manufacturing operations. |

| The calculation below shows a method for estimating the savings in setup cost by using subplates, angle plates, or columns with an accurate grid pattern versus using conventional techniques. The probable payout time for the investment is also shown for the setup shown in exhibit 1. Every individual making such an evaluation will need to rely on his own experience and understanding of his manufacturing operation to plug realistic numbers in the formula. |

| Payout equals the investment in table tooling with an accurate grid pattern divided by the savings in setup cost. |

| Setups like the one shown in exhibit 1 can be done in 0.1 hours or less using Stevens modules. The same setup using conventional techniques on a T-slotted table or pallet would require 3.8 hours. Therefore payout in this case would be $3,776.00 divided by (3.8-0.1) x $45.00/hr or 22.67 setups. |

| This means that if average savings per setup approximate $167.00, the investment in table tooling with an accurate grid pattern will be paid for in about 23 setups. If setups are changed once a week, the investment will be paid for in less than 6 months. |

| The next calculation shows a way of determining additional savings which might result from using modular setup components in place of dedicated fixtures. The probable payout time for the purchase of additional setup components required for the setup in exhibit 2 is shown. |

| The setup shown in exhibit 1 requires a fixture costing about $1,800. However the net savings in tooling expense will be $1,800 minus the extra costs associated with setting up modular setup components. The setup shown in exhibit 2 would require 3.6 hours in design and build time. The actual costs of the components used in this setup is about $5,000. However, an assortment of modular tooling with setup components offering reasonable flexibility in setting up parts in this size range would approximate $13,000. Accordingly, the payout is calculated as shown in the next paragraph. |

| Payout equals the investment in modular setup components divided by the net savings in tooling expense. The net savings in tooling expense would be $1,800 minus (3.6 hours x $45/hr) or $1,674. The payout would then be $13,000 divided by $1,674 or 7.7 fixtures. |

| This means that a kit of modular setup components will pay for itself by eliminating the need for building 8 dedicated fixtures. Payout time will depend on how many fixtures are normally made in a specific time span. |

| - CONCLUSIONS It has been well established that significant gains in manufacturing productivity can and have been made through use of modular tooling in manufacturing operations. This is particularly true in factories and shops where small batch quantities and continually changing production requirements necessitate frequent setup changes and reduced response time. A thorough understanding of the variety of ways that modular tooling may be applied to a broad range of manufacturing conditions will help users to apply it properly and profitably. |

| This paper used with permission of the Society of Manufacturing Engineers, Dearborn, Michigan. |