1 Cut Setup Time By Using Dedicated Fixtures On Modular Components

This setup can be made in 5 minutes or less using a 10070-4 Tooling Plate made into a dedicated fixture, mounted on two 20080 Angle Plates located on a Subplate. This approach should be considered under the following conditions:

- Repeat runs of the part to be machined are frequent.

- Toolroom facilities for designing and building dedicated fixtures are readily available.

- Storage space for additional dedicated fixtures is available.

|

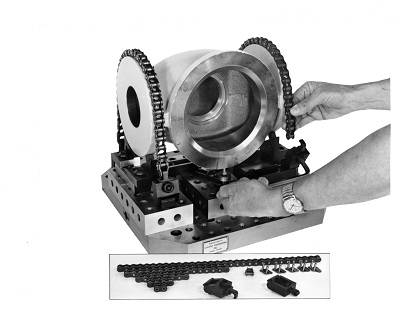

2 Cut Fixturing Costs By Setting Up With Reusable Setup Components

This setup of the same part shown on the left is done entirely with reusable setup components. No dedicated holding fixture is needed. This approach should be considered under the following conditions:

- The part to be machined is prototype or pre-production and may be run infrequently, if ever again.

- Workpiece design changes are likely, making dedicated fixture obsolete.

- Requirement for fixturing is immediate; no time to build dedicated fixture.

|

1 Reductions in Setup Time Using Dedicated Fixtures on Stevens Modular Components

PAYOUT=

INVESTMENT IN MODULAR FIXTURING

SAVINGS IN SETUP COST

Setups like the one shown on the left side of the opposite page can be done in .1 hours or less using Stevens Modular Fixturing. The same setup using conventional techniques on a T-slotted table or pallet would require 3.8 hours.

Payout=

Total Investment = $3,776.00

Savings (3.8 - .1) x $45.00/hr

=22.67 setups

This means that if average savings per setup approximate $167.00, the investment in Stevens Modular Fixturing would be paid for after about 23 setups. If you change setups once a week, the investment will be paid for in less than 6 months.

Note: Stevens will jig bore and bush your dedicated fixtures to fit Stevens Primary Table Tooling, on a contract basis.

|

2Elimination of Tooling Expense Using Setup Components on Stevens Primary Table Tooling

PAYOUT=

INVESTMENT IN MODULAR FIXTURING

NET SAVING IN FIXTURING EXPENSE

In determining net savings in fixturing expense, you will need to make certain estimates based on your own experience. For example, the setup shown on the opposite page would require a fixture costing about $1,800. However, the net savings in fixturing expense will be $1,800 minus the cost of setting up with modular setup.

components. The setup shown on the right side of the opposite page would require about 3.6 hours to design and build initially.

(Repeat setups would require about .3 hours)

Net savings in fixturing expense

=$1,800 - (3.6 hrs. x $45.00)

=$1,674.00

The actual cost of the modular components used in this setup is $5,234. An assortment of modular fixturing with setup components offering reasonable flexibility in setting up parts in this size range would approximate $13,800. Accordingly, we calculate the payout as follows:

PAYOUT=

INVESTMENT IN MODULAR FIXTURING

NET SAVING IN FIXTURING EXPENSE

= $13,800

$1,674

= 8.24 fixtures

This means that for setups of this type a Stevens Modular Fixturing package will pay for itself by eliminating the need for building slightly more than 8 dedicated fixtures.

Payout time will depend on how many fixtures are normally made in a specific time span.

|