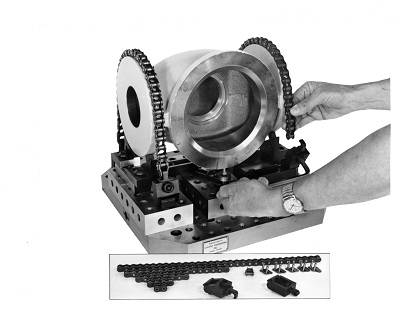

Stevens Subplate / Tombstone |

Two qualified edges contact edge locator plates on the machine pallet. Cap screws passed through holes in the edge locator plates and into threaded holes in the base of the fixture pull the fixture into precise alignment and position. |

|

Two Stevens Precision Bushings match bushing locations on a Stevens Subplate permanently mounted on the machine table or pallet. Two Stevens Precision Pull Dowels inserted through these bushings into corresponding bushings in the Subplate below quickly assure correct position and alignment. The Subplate may have its own locating features to match the machine pallet. |

|

Three removable fixture keys mount into bushings on the underside of the base. Machines which have 2 precision per-pendicular slots use this option. Expanding collet on fixture keys locks into Stevens bushed hole using Allen wrench. Keys may be oriented with a straight edge prior to setting fixturing on pallet. |

|

A removable center locator and fixture key mount into bushings on the undersidde of the base. Machines which have an accurate center bore and one precision slot use this option. Expanding collet on center locators locks into Stevens bushed hole using Allen Wrench. |

|

Same as option E, minus the key. |

|